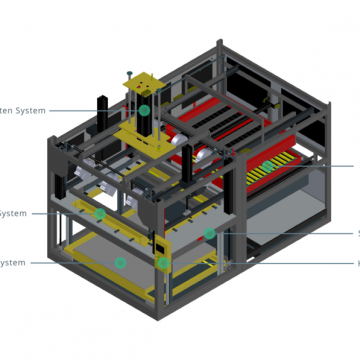

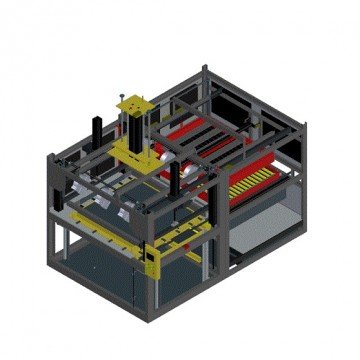

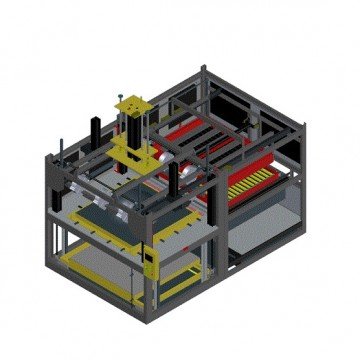

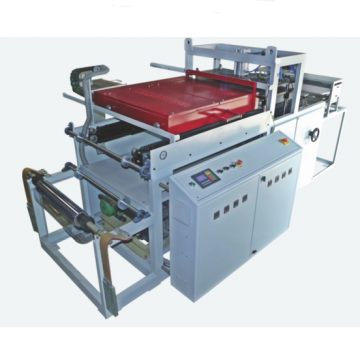

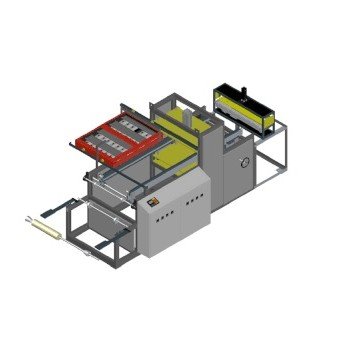

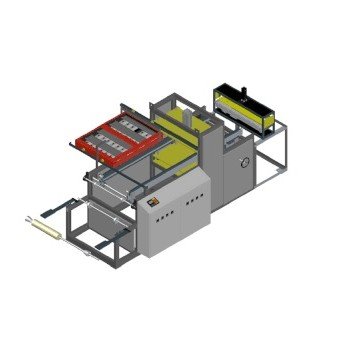

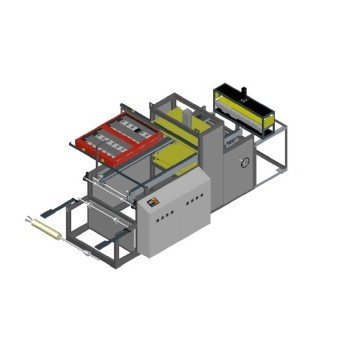

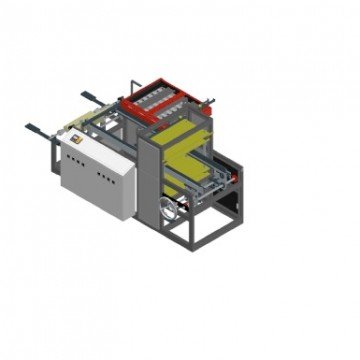

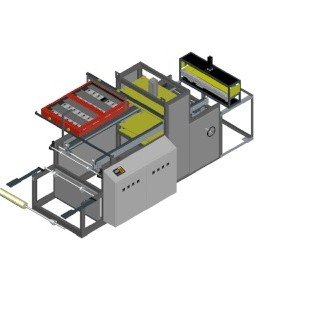

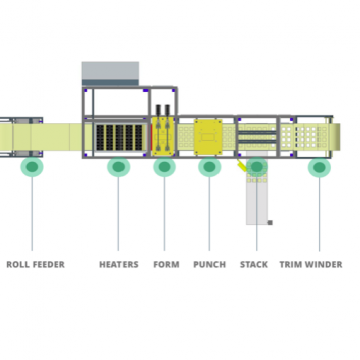

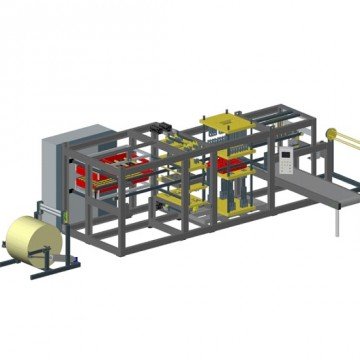

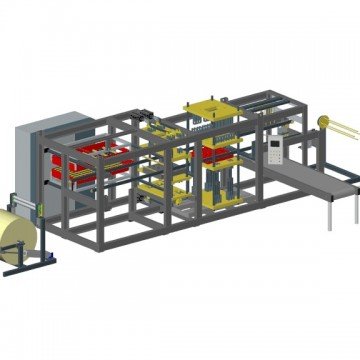

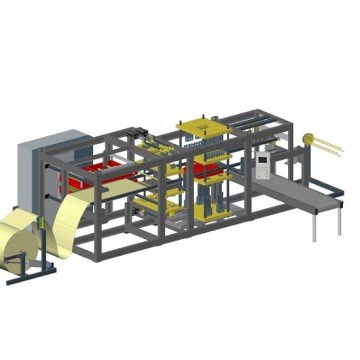

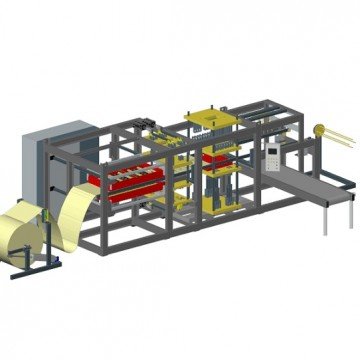

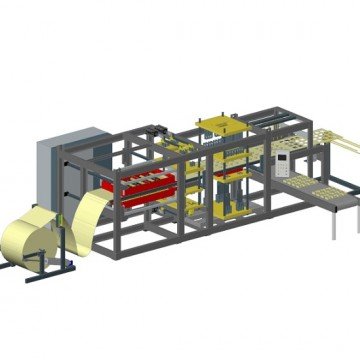

TFM Series

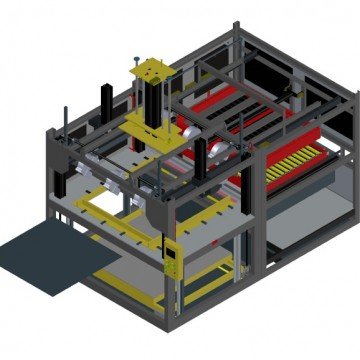

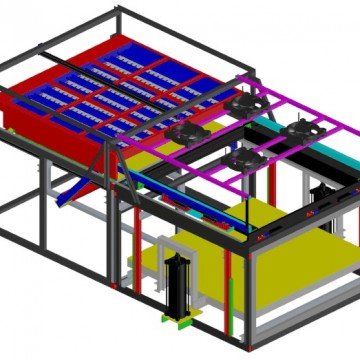

The TFM Series has been designed to form thin sheet products using pressure forming technology The automatic pressure forming machine type TFM uses roll feed material and are best suited for large scale production of disposable containers and packaging items. The machines can handle combined forming and punching moulds.

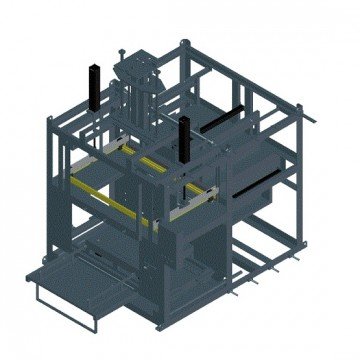

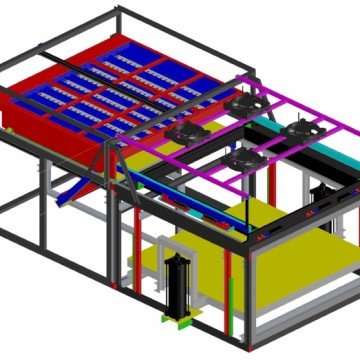

Sheet Transport

: Guided spiked chains carry the sheet material through the machine. The chain rails are placed in a water cooled jacket thoughout the heating zone. The chain indexing is by servo motor and drive

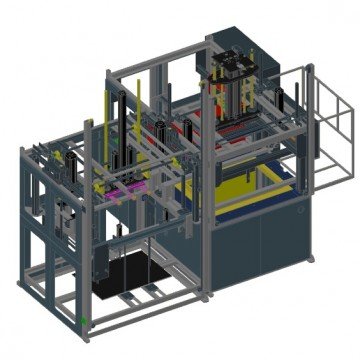

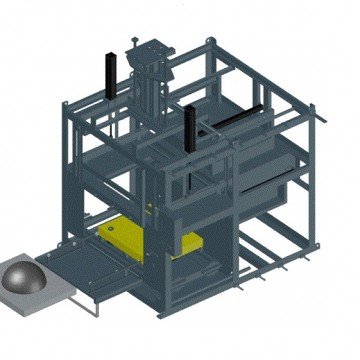

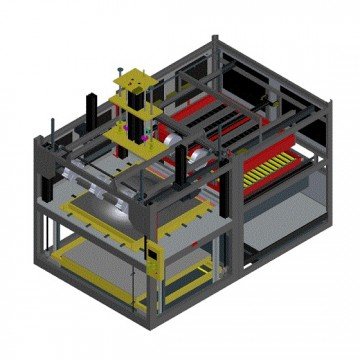

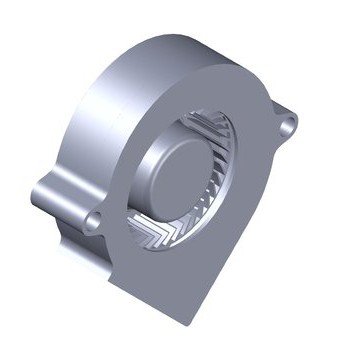

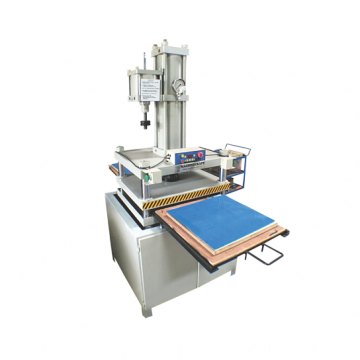

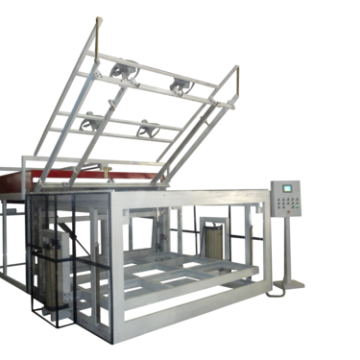

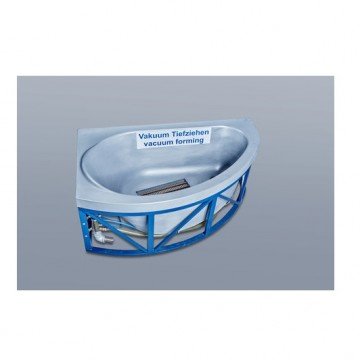

Forming Station

: The forming station is of robust construction guided in bushes and driven by servo motor. The forming station is designed to accommodate tools with combined forming and punching with water cooling. It has a plug assist drive on the top and ejector at the bottom of the table. The forming station is designed for easy tool changing.

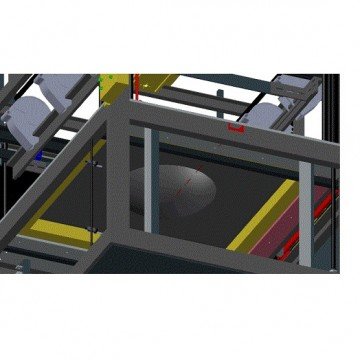

Heating System

: The heater elements are of ceramic infrared type and mounted on special reflectors. The heater temperature control is through PLC.

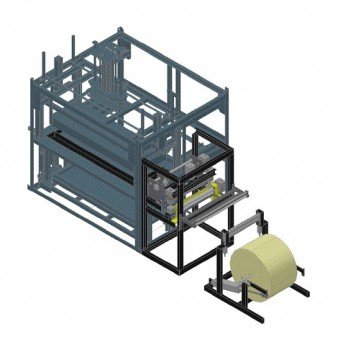

Trim Winder

: The trim of sheet after the forming station moves to the scrap winder, where it is wound neatly to facilitate easy removal of trim.

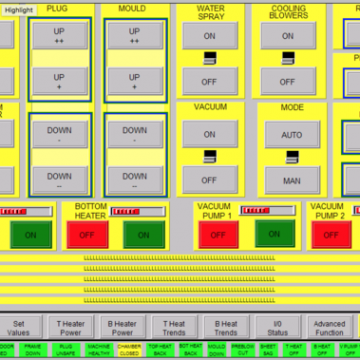

Control Panel

: Entire sequence of machine operation is controlled by PLC. The values set can be stores in the PLC and can be recalled when needed. Pressure for forming & ejection can be individually adjusted as required. Heater elements are divided into zones controlled by PLC

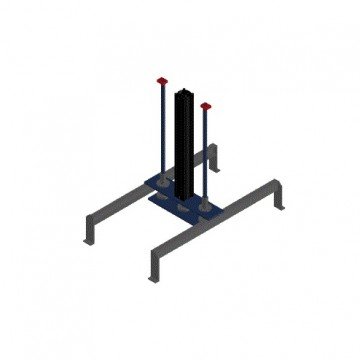

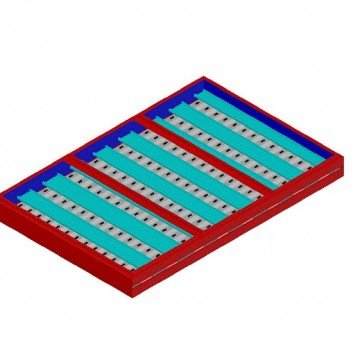

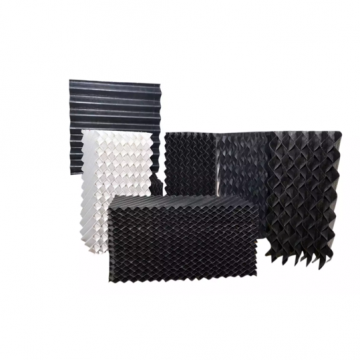

Tooling

: Tooling is combined forming and punching mould. Multi row moulds can be used on the machine. Same mould can be used for different article depth by changing ejectors. Complete tooling is made on CNC machines.