Back

QT10-15 Big Production Capacity Automatic Block Machine

Price : 0/Piece(s)

Minimum Order : 1 Piece(s)

Production Capacity : 1 Piece(s)/week

Product Description

QT10-15 Automatic Brick Machine is the most advanced and biggest capacity block machine now. 1. Full automatic PLC control block machine with hydraulic system 2. Multi-function: concrete hollow block, solid block, color face paver, curbstone, habiterra

QT10-15 big automatic paving brick machine advantage

Max. production capacity: 307CBM standard hollow blocks per 8 hours.

QT10-15 automatic paving brick production line introduce

A

QT10-15 Host brick machine

a. Automatic pallet system

b. Automatic material feeding system

B

B belong to A,

It is QT10-15 brick machine full automatic PLC controller

C

C belong to A,

It is QT10-15 brick machine hydraulic station

D

8m conveyor-2 layer conveyor

E

JS750 Mixer-38.6kw/h; Production capacity: 37.5-42.5cbm/h

F

PLD800 2 Warehouse batching machine

G

Block receiver-3m

H

Stacker-two pallets a time stacker

Optional

2 tons wheel loader; 3 tons forklift

Optional

Automatic pallet feeding machine

Optional

50 tons cement silo--Detachable

Cement screw conveyor--8m

Fiber pallet (1100-870mm)--1800pcs

Color feeder system

QT10-15 Color feeder machine--Automatic hydraulic machine

Color mixer--1.2m; 7.5kw

3m conveyor

Note

QT10-15 block factory all investment items solution

Total Power Consumption (A,B,C,D,E,F,G,H,M and pallet feeder machine)

98.5 kw/h; 788 kw/8 hours

Max. Material Consumption Per 8 Hours a. Concrete: 10% cement, 30% sand; 60% stone powder b. 400-200-200mm; 2 holes hollow block

Water: about 4992 kgs

Cement: about 24460 kgs

Sand: about 73382 kgs

Stone powder: about 146766 kgs

Factory total size

At least 1900 square meters, at least 4 rooms

Workers

5-6 workers in factory

Machine parts information

Motor: Shanbo brand (Chinese famous brand)

PLC: Vigor from Taiwan (3 control cores)

Frequency changer: Holip fropm American

Inductor and Switch: CHNT and Schnelder

Warranty

One year

QT10-15 block factory production flow Note

QT10-15 multi function concrete brick production plant technical information

Molding cycle

15s

Vibration frequency

4600-5200hz

Vibration force

90kn

Rated pressure

21mpa

Host brick machine size

5470(L)×2830(W)×2820(H)mm

Net Weight

5600kg

Pallet size

1100-870-25mm

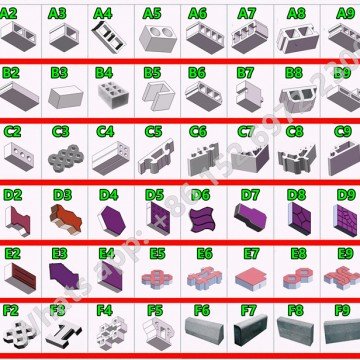

QT10-15 different block production capacity introduction

Block type

Size and Production Capacity

Hollow block

400-200-200mm

10 pcs/mold

19200 pcs/8 hours

Holland block

200-100-60mm

28 pcs/mold

53760 pcs/8 hours

Zig Zag brick

225-112.5-60mm

24 pcs/mold

46080 pcs/8 hours

I shape paver

200-160-60mm

18 pcs /mold

34560 pcs/8 hours