Back

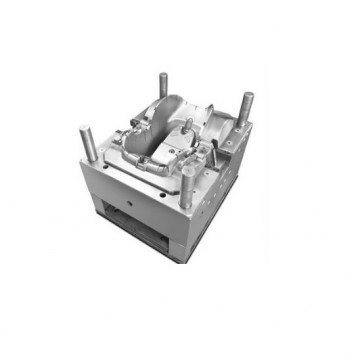

Professional Factory Auto, Motorcycle Parts & Accessories

Price : 0/Piece(s)

Minimum Order : 1 Piece(s)

Production Capacity : 1 Piece(s)/week

Product Description

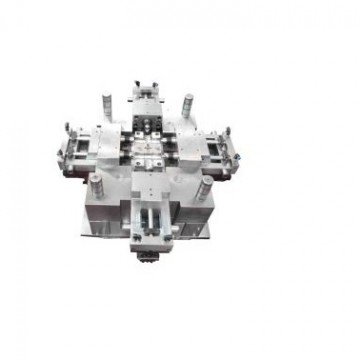

Basic Info Model NO.: ABIS-207 Pressure Chamber Structure: Horizontal Tolerance Grade: 7 Casting Surface Quality Level: 2 Certification: CE, ISO 9001:2008 Product Name: Auto and Motorcycle Parts Brand Name: ABISMOLD Material Available: Steel, Aluminum, Aluminum Alloy etc Model No.: Auto Parts 196 Usage: Automobile Industry Dimension: Can Be Customized for Your Requests Inspection: by Professional Measuring and Testing Devices Country of Origin: China OEM: Available Packing: Wooden Case or as Your Requests Trademark: Available Transport Package: Pallet, Wooden Case or as Your Requsts Specification: ISO9001: 2008

Basic Info

Model NO

ABIS-207

Pressure Chamber Structure

Horizontal

Tolerance Grade

7

Casting Surface Quality Level

2

Certification: CE, ISO 9001

2008

Product Name

Auto and Motorcycle Parts

Brand Name

ABISMOLD

Material Available

Steel, Aluminum, Aluminum Alloy etc

Model No

Auto Parts 196

Usage

Automobile Industry

Dimension

Can Be Customized for Your Requests

Inspection

by Professional Measuring and Testing Devices

Country of Origin

China

OEM

Available

Packing

Wooden Case or as Your Requests

Trademark

Available

Transport Package

Pallet, Wooden Case or as Your Requsts

Specification

ISO9001: 2008

Product Description

Item Name

Die casting products

General Products Application/Service Area

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine,

transportation equipment, Valve and Pump system, Agriculture machine

metal Parts, engine bracket, truck chassis bracket, gear box , gear housing ,

gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe,

hydraulic valve, valve housing ,Fitting , flange, wheel, fly wheel,

oil pump housing, starter housing, coolant pump housing, transmission

shaft , transmission gear, sprocket, chains etc.

Main blank Process for Aluminum Casting

Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting,

High Pressure Casting/Sand Casting, Extrusion Casting etc.

Applicable Material for casting

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302,

Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2

Or according to customer requirements

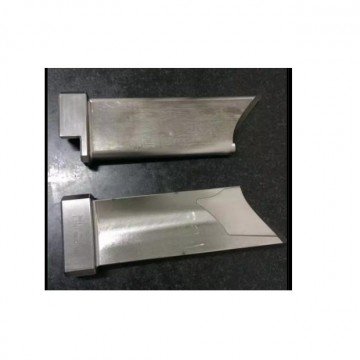

Casting Blank Size /Dimensions

2 mm-1500mm / 0.08inch-60inch , or according to customer requirements

Casting Blank Weight

Range from 0.01kg-50kg

Applicable Machining Process

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/

Broaching/Reaming /Grinding/Honing and etc.

Machining Tolerance

From 0.005mm-0.01mm-0.1mm

Machined Surface Quality

Ra 0.8-Ra3.2 according to customer requirement

Applicable Heat Treatment

T5~T6

Applicable Finish Surface Treatment

Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating,

Finish Painting, Anodize (White or Black Color)

MOQ

For casting parts: 100pcs

For Machining: 50pcs

Lead Time

45days from the receipt date of deposit for turbine box casting part