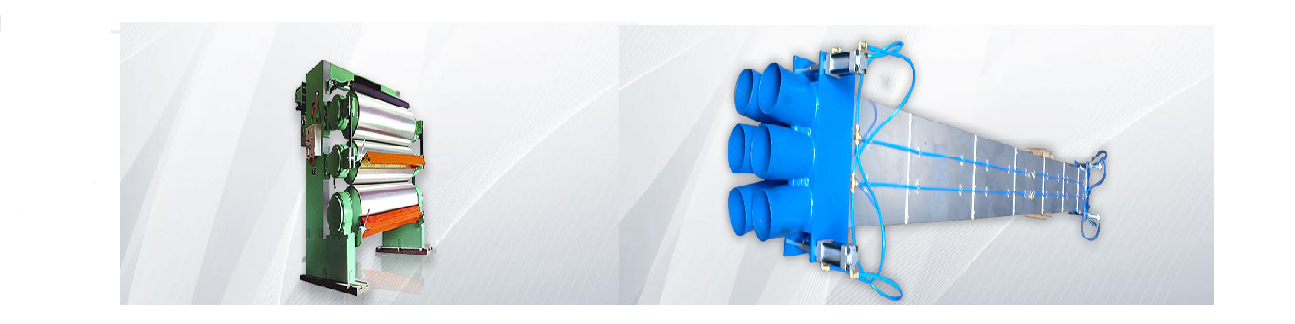

Size Press

The main purpose of a size press on a paper machine is to apply a solution of starch or other material onto the surface of the dry paper, to boost up B.F. in kraft paper & to provide glaze in white mapilite.Effective removal of sand, unbeaten paper chips, Hard cooked fibers and other non fibrous heavy materials. Low fiber rejection. Low Pressure drop. Available in 300LPM, 500LPM, 750LPM and 1000 LPM throughput.

Technical Specifications

Features

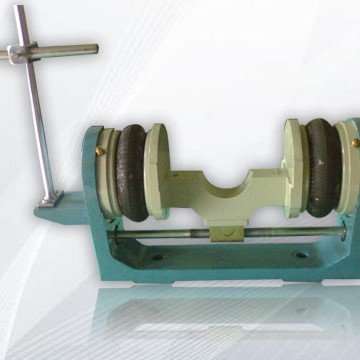

: Usually the main role for applying the material is used to increase the surface strength of the paper web. Other benefits also includes reduced dusting tendency, increased stiffness and reduced air-permeability.Size Press is designed as two rolls Press with Hydraulic or Pneumatic down Pressure system. Its press rolls are arranged horizontally where a movable Press roll is installed lower than the stationary one.